ProLogium says it

will start shipping its solid state silicon battery to European car makers for

testing by the end of this year.

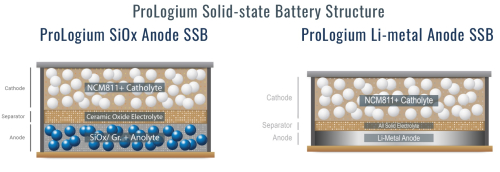

The new solid state

battery design with a ceramic electrolyte can nearly double the energy density

of an EV pack while significantly reducing its weight and the number of cells

in pack with increased cell energy says the company.

The Large Lithium

Ceramic Battery (LLCB) format reduces the number of cells and the number of

parallel connections in the battery pack, reducing component and assembly

costs. The flat shape and the excellent thermal conductivity of the solid-state

ceramic electrolyte combined can make the design of pack cooling system much

less complex, thereby optimizing space and saving over 100kg.

“Last year, we

announced the first solid-state battery with 100% silicon oxide anode designed

to enable higher energy density at the cell level. Now, we are pleased to

present the LLCB, another pioneering battery concept that will take EV battery

design to the next level in terms of long range, light weight and design

flexibility,” said Vincent Yang, CEO and founder of ProLogium Technology.

“ProLogium is

currently cooperating with FEV to carry out verification tests of the LLCB and

design applicable solutions. Samples are targeted to be delivered to European

car OEMs for testing as early as the end of 2023,” said Polun Cheng, Global

Project Management AVP of ProLogium Technology. European partners include

Mercedes-Benz.

ProLogium is

setting up its first overseas solid-state battery gigafactory in Dunkirk,

France, in a €5.2bn investment. The total planned capacity of 48 GWh will be

deployed in phases to supply the European EV market. “With a clear roadmap for

capacity ramp-up and technology development, we are making an all-out effort to

accelerate the electrification revolution by providing improved energy solutions

to our partners,” said Yang.

“The LLCB will

enable greater design flexibility for EVs,” said Simon Wu, Assistant Vice

President of ProLogium Technology Product Centre.

“For the same space

as the mainstream 2170 EV battery pack, the LLCB pack’s volumetric energy

density can be nearly doubled, and for the same total energy, the LLCB pack’s

weight can be cut by up to 115 kg,” he said.

No comments:

Post a Comment